Enterprise-grade connected technology associated with the ever-expanding internet of things has continued to expand its reach. The latest iteration of IoT has hit manufacturing in the form of the Industrial Internet of Things, or IIoT, allowing workers to harness the power of the internet to streamline and strengthen production processes and more effectively meet consumer demands.

On paper, IIoT seems like the technology poised to drive innovation in manufacturing – and industrial organizations are following this thread in their investments. Enterprise IoT spending is expected to surpass $772 billion in 2018 and reach $1 trillion by 2021.

That said, for IIoT to be a sustainable solution, upgrading manufacturing technology needs to be more than just “keeping up with the Joneses.” The question then becomes: Is IIoT an operational necessity or just a flashy add-on? Manufacturers and other industrial firms need to look clearly at their existing technology and determine where IIoT can translate to substantial – critical – improvements.

Human and automation symbiosis

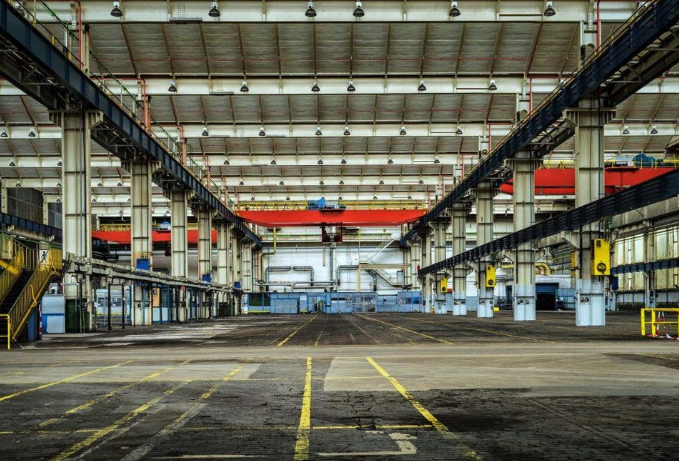

Businesses in the manufacturing space are among the most enthusiastic adopters of IIoT technology, accounting for $189 billion in investments related to these cutting-edge assets in 2018. An estimated 38 percent of factories are already leveraging IIoT processes. As a result, you see some of the most mature IIoT workflows in this space – warehouses and production facilities where man, machine and advanced data analytics are working in harmony to achieve incredible results.

Perhaps one of the most prominent examples of IIoT at work is taking place at one of the world’s most successful companies: Amazon. In what MIT dubbed a “human-robot symbiosis,” Amazon has transformed their warehousing and fulfillment centers through the deployment of automation, allowing for the company to cut operating costs by 20 percent.

What makes the Amazon deployment so novel is that IIoT is being viewed as an enhancement of industrial processes rather than a replacement for human labor.

“It’s a natural outgrowth of efforts to harness cheap computing power to make robots more collaborative,” Wily Shih, a professor at Harvard Business School who studies manufacturing, said at the time.

Smaller companies have similarly employed IIoT to improve operations in their facilities. Robotics maker Fanuc, for instance, sought to address the issue of downtime by employing a cloud-based analytics software that would predict imminent component failures and flag for maintenance. The Zero Downtime system Fanuc pioneered ultimately resulted in the company being awarded GM’s prestigious Supplier of the Year Innovation Award in 2016.

250% increase in productivity with automation

Smart factories represent the pinnacle of IIoT technology and early facilities, such as those discussed above, have revealed that connected industrial-devices, deployed at scale can have an immense impact on the shop floor. This is why an estimated 76 percent of manufacturers worldwide are developing these advanced sites. In fact, almost 60 percent of the industry have $100 million or more invested in these efforts.

Embarking on the IIoT journey: Where to start

As both of these use cases show, IIoT is more than just a flashy add-on to existing workflows. It’s hard to argue with the ability to seamlessly turn digital designs into reality via automated production lines or a whopping 250 percent increase in productivity.

Manufacturers that have yet to roll out concrete IIoT development plans should certainly consider doing so quickly, as it seems that this technology may soon drive the industry. Still, this can be an intimidating undertaking. Even smaller scale IIoT deployments have lots of moving parts – literally and figuratively – that even the most advanced internal IT teams might struggle to juggle without external assistance and guidance. Even worse, some some manufacturers may not even know where to start with their needed upgrades.

This is why we built Oden Technologies: to assist manufacturers that want to embrace IIoT technology, but aren’t sure where and how to begin. Our hardware and industrial IoT software allow manufacturers to collect actionable shop floor data and use it to improve and streamline their production flows, thereby building the data-backed foundation needed to move into more advanced IIoT deployments.

Connect with us today to learn more about how our technology can future-proof your manufacturing operation.