An Open Invitation: Oden Pledges Support For COVID-19 Manufacturing Efforts

Oden supports COVID-19 manufacturing efforts by offering free remote deployment of its predictive analytics solution to increase output of essential products.

As each day passes, the impact of COVID-19 grows. Front-line health care workers are left unprotected and undersupplied as they work tirelessly to keep those who need medical care safe. The strains on our medical system have also increased the demand for essential supplies and manufacturers of these necessities are scrambling to keep up with the overwhelming demand. Other manufacturers, including Ford and Anheuser-Busch, are offering support by shifting operations to support growing demand for hand sanitizer, masks, ventilators and more.

As part of our continued effort to support the manufacturing community, Oden will be offering free remote deployment of its Predictive Quality & Performance solution for manufacturers producing essential products in response to COVID-19.

In times like these quality and efficiency matter more than ever. By leveraging machine learning technology, manufacturers can minimize scrap and quality failures while increasing throughput to support an influx in orders for the supplies needed to win the fight against COVID-19.

Prevent Quality Failures To Increase First Pass Yield

By analyzing live and historical production data, Oden’s platform identifies key process variables that impact quality control, then predicts critical metrics to prevent problems. Predictive alerts notify factory personnel, allowing them to take corrective action in advance and prevent extensive quality failures.

Increase Throughput Without Sacrificing Quality

By identifying the conditions that contributed to your most efficient production runs, the platform provides recommended settings for key variables such as line speed, temperature or pressure. Operators can leverage these settings to replicate optimized production runs more consistently to increase output without sacrificing quality.

Improve Productivity Across The Factory Floor

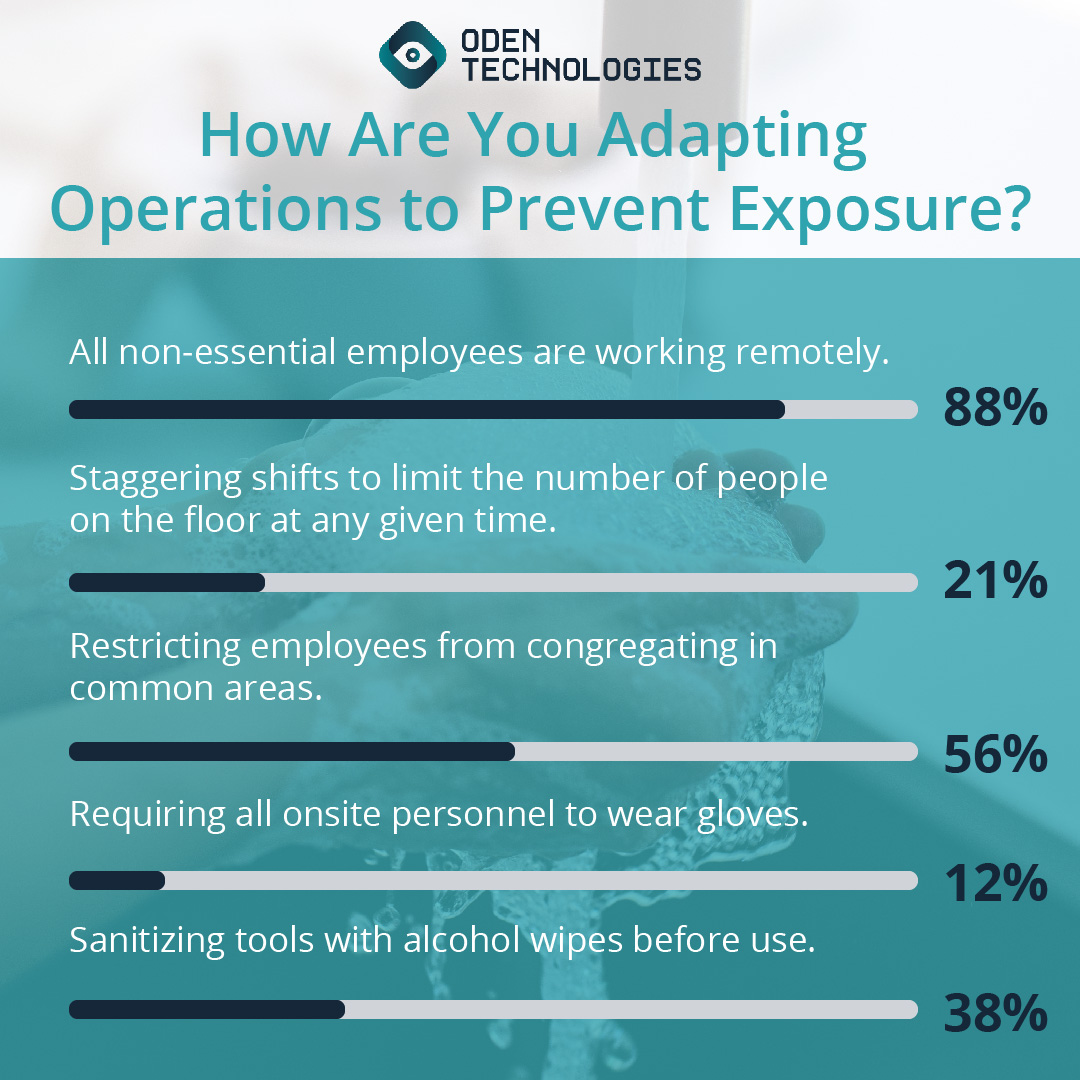

During a recent virtual panel event, more than 80 industry members gathered to share their strategies for how they are coping with COVID-19.

Live production dashboards enable time-constrained engineers to monitor several lines simultaneously while reducing the number of floor personnel. Machine learning quickly provides relevant data to diagnose downtime and efficiency problems, conduct root-cause analysis and surface recommendations to keep operations running smoothly.

“We realize manufacturers are under enormous pressure right now and our team is dedicated to supporting the production of essential products to meet overwhelming demands,” said Oden Cofounder and COO Peter Brand, “Engineers and operators need better digital tools to maximize production capacity and meet demand so we can get supplies into the hands of front line workers who need them now.”

Contact us as [email protected] with the subject COVID-19 if you would like to learn more.

Read Cofounder and CEO Willem Sundblad’s original blog post on COVID-19, An Open Note from Oden.

To gain access to Oden’s predictive analytics solution, manufacturers must have a minimum level of connectivity including either a data historian or OPC UA server.

______