Our prescriptive analytics technologies improve OEE and other manufacturing performance metrics by identifying your “optimal run”. By analyzing production run history, our machine learning platform will identify your best performing segments, as well as the key settings that contributed to peak performance. We will ingest data from multiple data sources, including machines and sensors, MES and ERP systems, data historians and more.

Additionally, associating offline quality data to specific process parameters provides clear insights into the final state of products and whether or not they conform to quality standards. Our machine learning technology then analyzes all of the data to determine your best and worst-performing segments along with key variables that impact quality, performance and utilization.

After key parameters and settings have been identified, our out-of-the-box prescriptive analytics engine will generate recommended settings for controllable variables on the factory floor. This allows you to improve line speed targets without sacrificing quality by replicating your most efficient runs more consistently.

Our machine learning technology will help maximize machine throughput by reporting the biggest savings opportunities on your factory floor. The prescriptive analytics process is iterative: machine learning technologies are constantly looking for new ways to improve the process as changes are implemented on the factory floor.

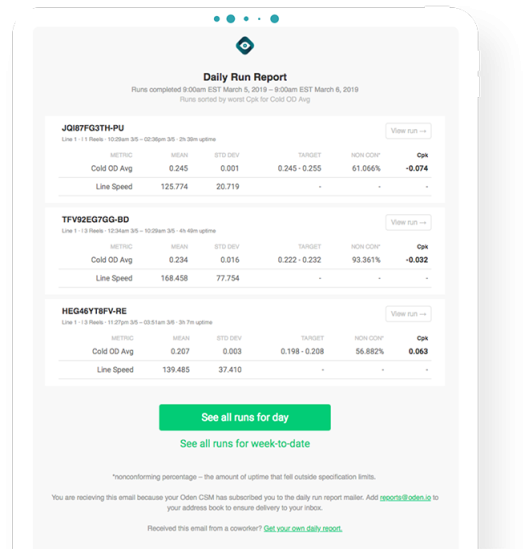

A real-time alerting framework is built upon the recommended settings that prescriptive analytics have determined. These alerts provide early warnings of departure from optimized settings, allowing factory personnel to proactively address production issues. Our hierarchical system allows operators, engineers and plant managers to be notified at different escalation points depending on the severity of the issue. This will help reduce scrap and material waste while simultaneously improving product quality.

Additionally, continuous evaluation and changes in current thresholds will fine-tune alerts to continually improve OEE and manufacturing performance.

Oden is like my smartphone,

I don’t remember how I did things before I had it.

PROCESS ENGINEER,

LAKE CABLE