Operationalize your most profitable production parameters by relying on prescriptive performance analytics to increase throughput without sacrificing quality.

Increase first-pass yield with recommended process parameters that maximize throughput without compromising quality.

Improve labor effectiveness by giving teams the dashboards and tools they need to monitor, analyze and optimize production.

Reduce material waste by minimizing variability in production processes to promote material usage efficiency.

Maximize profitability by eliminating waste and other inefficiencies to increase overall contribution margins.

Machine learning algorithms leverage centralized factory data from machines and sensors, ERP/MES and quality systems to create a digital thread of your production processes. Data is cleaned and contextualized into a consistent format, organized into a taxonomy that assigns semantics to the data and aligned with metadata such as the product, shift or quality state.

The digital thread translates your manufacturing expertise into an actionable representation of your production line to serve as a roadmap for your prescriptive performance solution.

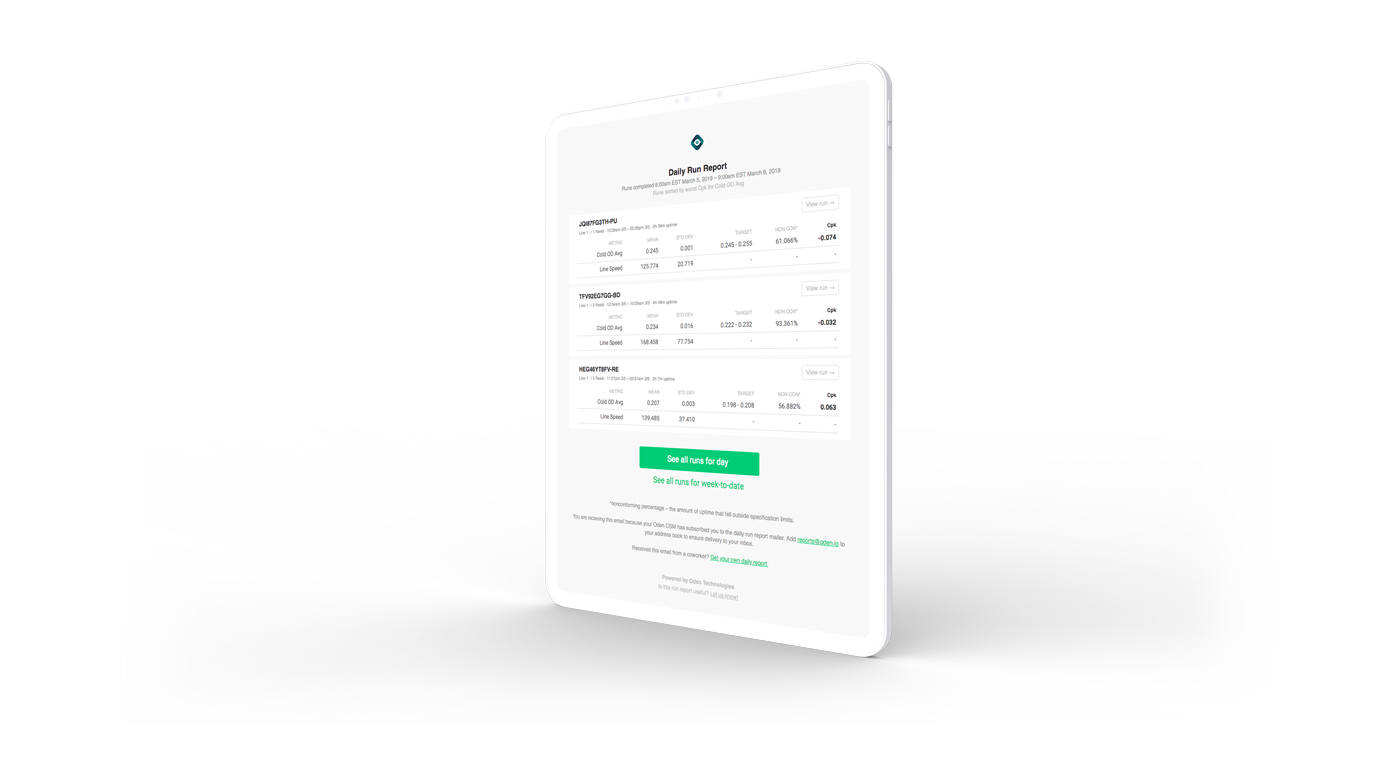

Engineers or shift supervisors are alerted when operations are trending outside of the recommended settings using machine-learning based predictive models. This allows your teams to take corrective action quickly to avoid excessive scrap, defective product or other more extensive problems.

Alerts can be customized based on factory floor conditions or a chain of command to continually improve OEE and manufacturing performance.

Over time people, processes and data change, so models must be retrained and adapted as needed. Rebuilding models based on new datasets ensures that predictions and recommendations are always accurate.

A cloud-edge hybrid solution with rapid iteration reduces the amount of time it takes to build, validate and deploy new models and enables you to get the most value out of your prescriptive performance analytics.

You are responsible for running the plant at optimal efficiency, deploying resources and constantly putting out fires without accurate process data.

Uncover and improve every inefficiency in your plant. Have confidence in knowing the exact status of production. Proactively see where and why issues arise.

You need to collect data from multiple sources and monitor endless process variables to ensure production is running to standard and eliminate variation.

Detect and eliminate every bottleneck as soon as possible and make production nearly perfect. Gain 100% control of your process and eliminate any variation.

You need to know how production is constrained and pinpoint where the plant can increase output, reduce costs and gain a competitive edge.

Always hit output and cost reduction goals. With real-time monitoring, you will see every problem, defect and win within your factory. Gain confidence in knowing it is true OEE.

Must provide accurate answers quickly to minimize qualified failures and ensure defects don’t reach customers.

Stop reacting to issues and instead proactively perfect product quality. Quickly find answers to why defects happened and how to prevent them in the future.

Deploy prescriptive performance analytics in