Machine-to-machine communication, or M2M, is at the core of what makes a smart factory smart. The smart factory model relies on a machine’s ability to track and report on data that is relevant to its operation and productivity. Without this capacity, the machinery is useless and cannot contribute to the insights that may be generated through a cloud-based platform.

In this post, we will look at how M2M communication influences the smart factory and the ways it can be applied in manufacturing. This will help give you an understanding of the smart factory from the ground up.

How It Works

M2M communication is just what it sounds like; it is the act of two or more machines or systems sharing information with each other. This transfer of information can occur through a wired medium, but it is more commonly done wirelessly. M2M is also not just limited for physical machinery, but can be between individual chips, sensors, or components within a machine.

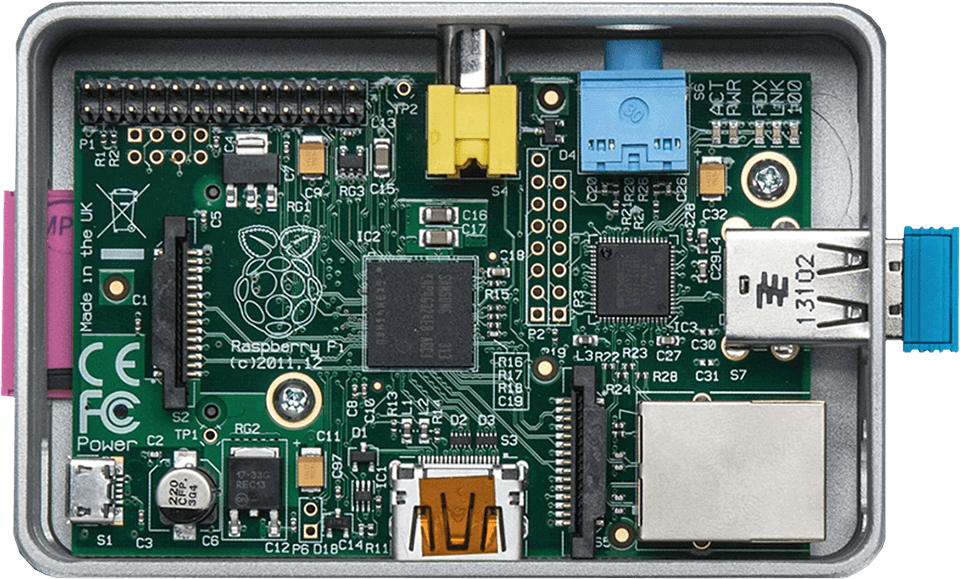

In manufacturing, many companies offer plugins that can enable traditional machinery with the ability to connect wirelessly to the internet and with online, cloud-based platforms. For instance, Oden Technologies offers a simple device that can be plugged into any machine or PLC to communicate wirelessly to their cloud-analytics platform. Once the machinery is enabled with wired or wireless communication, it now has the physical means to communicate with each other and with any system that is connected to the same network.

Applications In Manufacturing

M2M communication influences the way that a machine reports on and shares data in a manufacturing environment. It is incredibly important for plant managers to understand the current state of their factory, and one way to give them this information is to allow machines to communicate it directly to the manager through a software interface. Having accurate and relevant data will allow employees to gain meaningful insights on ways to improve their business.

Downtime in manufacturing occurs when a system or machine is not operating at its expected efficiency. This results in significant costs for manufacturers, and because of this, it is vital that manufacturers have systems in place to accurately report on the state of their factory at any given time. With M2M communication, each individual sensor on a machine reports its data to a central platform to solve this problem.

When a machine is operating at a lower efficiency or malfunctions, it will talk to the other machines and to the platform itself. This is for two reasons: 1) So that the factory employees can be notified and make the necessary manual adjustments or fixes, and 2) So that the other machines can make automated adjustments, like changing their rate of production or operating times.

M2M Automation

A major theme in M2M communication is automation. Automation can be good and bad depending on how it is implemented, but its purpose is always to improve efficiency, lower costs, and optimize production. Every manufacturing company is looking to reach these goals, and to do this, the proper technology must be deployed in their factory.

M2M communication is crucial to automation because it allows developers to dictate how a machine should operate based on certain conditions. For example, if a machine malfunctions, the system would be able to detect what part of this machine is inoperable and could even place an order for a replacement component.

The Value of M2M Communication

M2M communication creates the foundation for a smart factory that can be powered by artificial intelligence and machine learning. This form of a smart factory can bring tremendous value for the manufacturer such as increased productivity, reduced material waste, predictive maintenance and more. A smart factory is powered by big data, and any AI system is only as useful as the data that it has access to and it’s ease of use by factory employees.

A core component to machine learning is giving a computer system the ability to learn without explicit programming of that knowledge. The only way to do this is for a system to have access to information about itself and its environment, and that is only possible through M2M communication.

M2M For Optimization

On a more general level, the true value the M2M communication brings is the capacity for optimization. Whether it is through manual maintenance on machinery from real-time notifications, or it is an automated chain of actions that developers design to complete tasks, the ability for machines to exchange information is at its core.