Digital transformation, particularly within manufacturing, assumed its place as the driving force behind industry innovation. An estimated 42 percent of CEOs worldwide have greenlit such programs, according to Gartner. Manufacturers are, of course, have enthusiastically taken part in the gold rush and seen their efforts rewarded in critical bottom-line metrics: Decreased downtime, scaled up production, reduced costs and improved ROI.

As Industry 4.0 matures, moving forward with digital transformation becomes less about “if” and more about “when.” Firms on the outside looking in on these developments need to learn from the lessons of early adopters that have found sustainable success.

Innovation Takes Root

The first digital transformation technologies entered the mainstream in the early 2000s. Now-standard fixtures such as cloud computing services started largely as experimental early-stage digitization efforts which were eyed by many but adopted relatively slowly among manufacturers. After all, in 2004, it was hard for many industry leaders to picture how the ability to store and access data remotely would meaningfully improve manufacturing practices when much of the “innovation” seemed focused on social media and sharing media.

This changed with the growth of formalized cloud offerings and the rise of the internet of things. Suddenly, the digital transformation wasn’t just about connecting people and exchanging ideas, but creating automated networks of technology.

Today, manufacturers are among the biggest supporters of these technologies. Connected sensors and robust back-end systems have given firms the power to streamline their operations in the age of lean manufacturing, enabling them to navigate turbulent markets and more effectively meet customer demands. One-third of modern manufacturing companies attest to managing highly digitized workflows. By 2020, that figure is expected to surpass 70 percent.

What about the businesses that haven’t yet embraced digital transformation? While seemingly inevitable, going all-in on full-scale adoption is daunting. Luckily, early adopters have essentially paved the way for deployment and their trajectory can serve as an effective roadmap.

Understanding the Transformation Roadmap: Getting It to Work for You

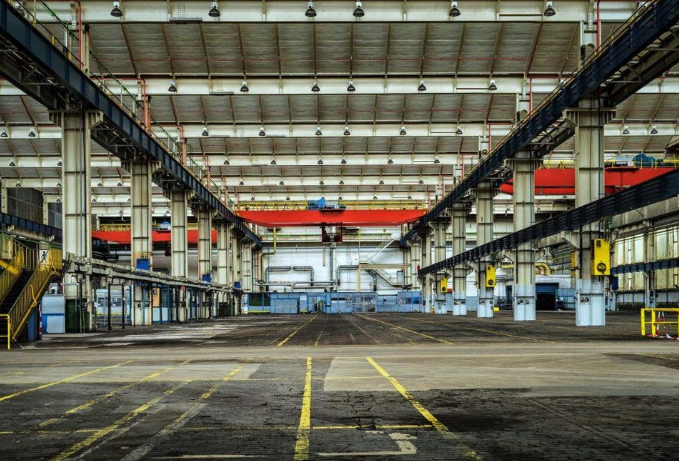

The most common digitization roadmap centers around technology that generates data analytics and insights.. Manufacturers pursuing this use case install connected sensors and platforms that allow them to collect and analyze shop floor insights of all kinds, from data on machine performance and wear to information on the supply chain.

Harley-Davidson was among the first enterprises to take this approach. Back in 2010, the company outfitted the 10 year-old production assets in its York, Pennsylvania plant with sensors capable of collecting key mechanical insights, including machine temperature and rate of vibration. These data points allow Harley-Davidson engineers and maintenance specialists to proactively address problematic equipment and therefore reduce downtime, while simultaneously ensuring that production lines ran at capacity.

Digitization strategies centered on supply chain integration are also common. Manufacturing firms employing this approach leverage cutting-edge online communication and data-sharing tools to craft collaborative processes that enable product design, and production teams to connect with third-party partners that provide mission-critical services. Smart warehousing technologies, advanced procurement modules, and prescriptive analytics engines drive these streamlined workflows.

Taking the First Steps

Manufacturers can learn a lot from these deployments and embark on digital transformation with a relatively clear picture of the end product. However, there are numerous pitfalls implementation teams must manage. For example, firms with aging shop-floor workers must focus on change management. Manufacturers with legacy systems will also encounter problems as modern industrial IoT assets normally do not mesh with older technologies.

That said, manufacturing firms intending to modernize cannot let these roadblocks dissuade them, for those that continue to put off digital transformation will soon find themselves unable to compete with more advanced, forward-thinking industrial players. But how can manufacturers looking to stay competitive avoid implementation pitfalls?

Industry 4.0 platforms that streamline digital transformation are the ideal solution. We created Oden to provide hardware and software for manufacturers of all sizes to launch their digitization efforts through an easy-to-install system, machine agnostic sensors, and robust in-house configuration services.

Connect with the Oden team to learn more about our software and services that have already given manufacturers the actionable insights they need to improve production.