In the present fast-changing world, innovation takes place and technology changes seemingly every day. This often makes people feel as if they’re “out of the loop” on technology changes in various industries. In the realm of manufacturing, there have been three primary periods of massive innovation: first was the industrial revolution, then the electrical revolution, and lastly the computer revolution.

In the last half-decade, the manufacturing industry began stepping into the early stages of the what’s called “The Fourth Period of Massive Innovation — Industry 4.0”. This is the revolution that brings together digital, physical and biological systems in harmony to hyper-boost productivity. It will inevitably impact human life by implementing what is called “smart factories”.

Smart factories are already transforming the way manufacturers approach production processes, allowing them to be adaptive, profitable and sustainable. Big data and analytics are playing a pivotal role in helping manufacturers to improve efficiency and driving down costs… but what are big data and analytics?

Big Data In Manufacturing

What is Big Data and Why Does it Matter?

Big Data is a collection of information (data) from traditional and digital sources inside and outside companies that represent a source for ongoing discovery and analysis.

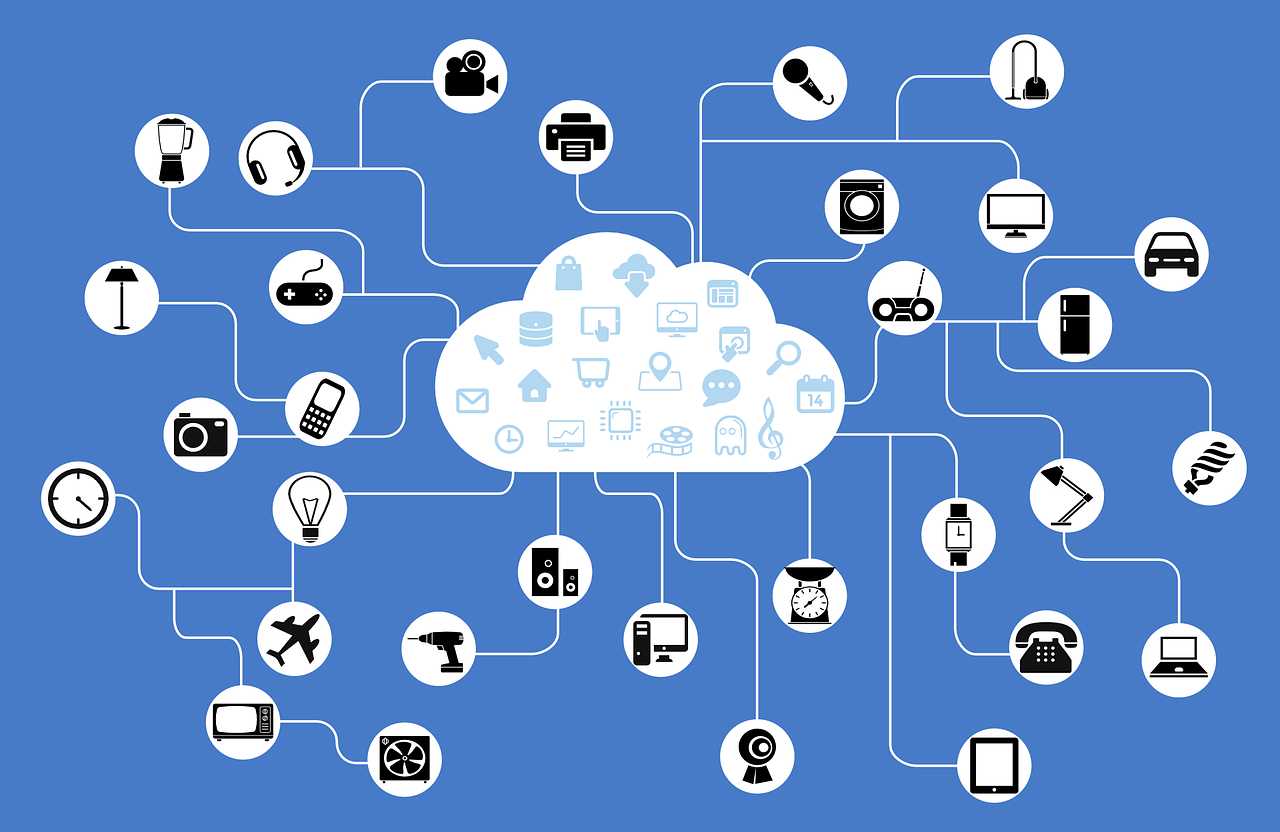

At the heart of the big data, there’s the Internet of Things (IoT) — a collection of various data-gathering sensors embedded in everyday objects. The vast number of devices with sensors (estimated to grow to 50 billion by 2020) allow communication with other devices/people through the Internet. Today data is collected everywhere, via IoT and the cloud.

This data is what allows computers to perform tasks efficiently based on current information that it receives through data gathering tools. Big data is powerful, but building computers that can effectively interpret massive amounts of data is challenging.

- Turning the raw data collected from the manufacturers into actionable insight requires multiple levels of processing:

- Collecting the data from machines, production lines and factories

- Conditioning the data

- Combining disparate data streams into manufacturing models that enable meaningful analysis

- Conducting the analysis; and

- Interpreting the results to enable understanding and action

This is where analytics comes in.

Analytics In Manufacturing

There’s a clear distinction between being able to collect data and compile it, but being able to use that data effectively is a completely different game. Using data effectively is the sole purpose of analytics. Given the sheer number and complexity of manufacturing activities that influence production, manufacturers need a more granular approach to diagnosing and correcting process flaws, saving both time and money.

Improving Operational Performance

Improving operational performance yields multiple benefits, so it should be every manufacturer’s goal. That’s why leveraging big data is critical. In particular, big data leads manufacturers to be more efficient with how they use and manage resources.

The ability to analyze data being collected is where potential weaknesses that exist in a factory supply chain are revealed. Using the harmonious combination of IoT, big data, and analytics enables manufacturers to make better decisions. Beyond manufacturing speed, “Industry 4.0” technology also allows machines to detect product failures/defects. Some other additional benefits are:

- Increasing the accuracy of maintenance and repair schedules

- Predict workloads based on market trends

- Product quality management

- Process controls

- Operations management

- Process design and improvements

- Predictive maintenance/asset management

- Supply chain management/sourcing

- Safety and facility management

- Targeted capital spending

Preparing Manufacturers For The Future

Although Industry 4.0 enables factories to produce more, waste less, and innovate faster, there are many challenges associated with building smart factories. One challenge is sourcing the sensors required to implement those smart factories for industry specific needs. This is where we come in.

Using a combination of industrial IoT software, wireless connectivity, and big data, Oden Technologies is helping manufacturers optimize production efficiency. At Oden Technologies, we provide a variety of sensor devices that plug into almost any kind of machine and are capable of sending real-time data wirelessly and securely to the cloud. We help compile important productivity metrics into one clear interface, with no complicated integrations.

Regardless of if manufacturers are preparing for Industry 4.0, it’s coming and it’s in their best interest to prepare for it and see what the available technologies are available to optimize for it. For those who don’t take this seriously, they may end up just like Sears did.